Plastics are ubiquitous in modern life, used for everything from packaging to automotive components to medical devices. With so many different types of plastics on the market, it can be difficult to know which ones are the best for your specific application. In this article, we'll take a closer look at some of the most high-quality plastic types, including their benefits, uses, and key features.

-

1. Acrylic

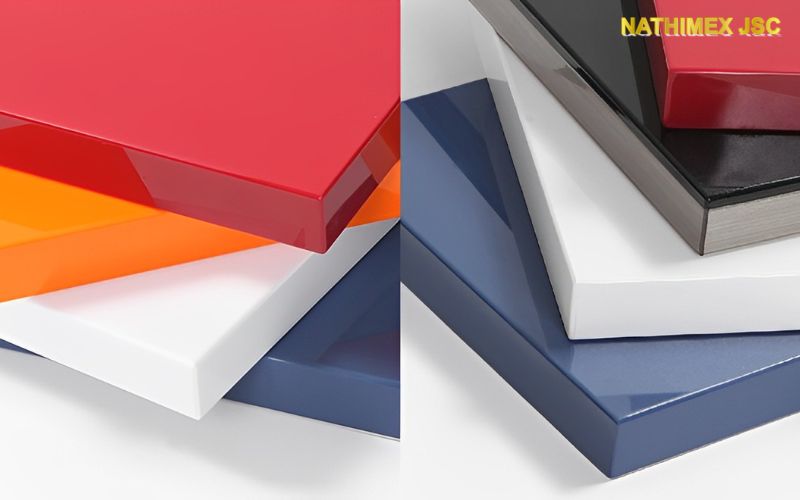

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic that is commonly used as a substitute for glass. It is a lightweight material that is easy to fabricate and offers excellent optical clarity, making it ideal for applications where transparency is important. Acrylic is also resistant to UV radiation, weathering, and impact, which makes it a popular choice for outdoor applications such as signs, windows, and skylights.

-

2. Polycarbonate

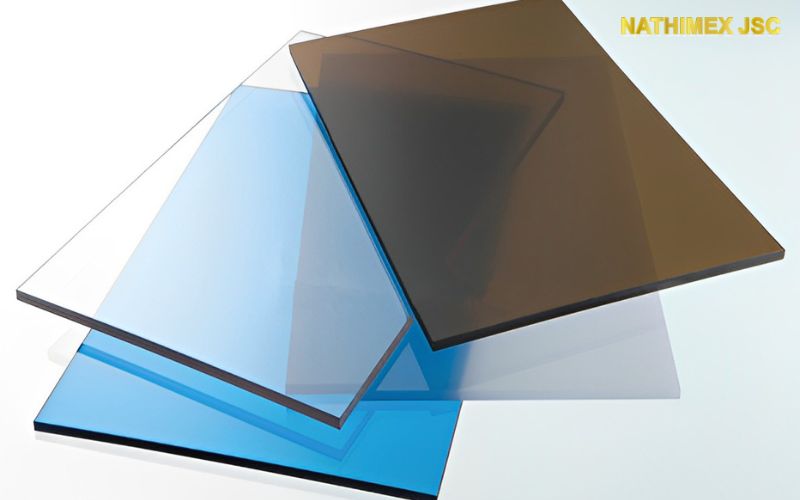

Polycarbonate is a durable and impact-resistant thermoplastic that is commonly used in applications that require high strength and toughness. It is often used in automotive components, safety glasses, and bullet-resistant windows. Polycarbonate is also lightweight and has excellent optical clarity, making it an attractive choice for applications that require both durability and transparency.

-

3. Polyethylene

Polyethylene is a versatile and durable thermoplastic that is commonly used in a wide range of applications, including packaging, pipes, and plastic bags. It is lightweight, flexible, and has excellent chemical resistance, making it a popular choice for food packaging and other applications where chemical resistance is important.

-

4. Polypropylene

Polypropylene is a versatile thermoplastic that is commonly used in a wide range of applications, including packaging, automotive components, and medical devices. It is lightweight, durable, and has excellent chemical resistance, making it an attractive choice for applications where chemical exposure is a concern.

-

5. Polyurethane

Polyurethane is a versatile and durable thermoplastic that is commonly used in applications that require high strength and flexibility. It is often used in automotive components, industrial coatings, and adhesives. Polyurethane is also resistant to abrasion and impact, making it an attractive choice for applications that require both strength and durability.

-

6. Polystyrene

Polystyrene is a versatile and lightweight thermoplastic that is commonly used in a wide range of applications, including packaging, insulation, and disposable cutlery. It is also an attractive choice for applications that require good electrical insulation properties.

Benefits and Uses

Each of these high-quality plastic types offers a range of benefits and uses. Acrylic is an attractive choice for applications that require optical clarity and UV resistance, such as signs, windows, and skylights. Polycarbonate is an attractive choice for applications that require high strength and impact resistance, such as safety glasses and automotive components. Polyethylene is an attractive choice for applications that require chemical resistance, such as food packaging and plastic bags. Polypropylene is an attractive choice for applications that require chemical resistance and durability, such as automotive components and medical devices. Polyurethane is an attractive choice for applications that require high strength and flexibility, such as industrial coatings and adhesives. Finally, polystyrene is an attractive choice for applications that require lightweight and electrical insulation properties, such as packaging and insulation.

Tips for Working with High-Quality Plastics

Working with high-quality plastics requires some specialized tools and techniques, but with a little practice, it can be a rewarding material to work with. Some tips for working with high-quality plastics include:

-

Use the right tools: Different plastics require different tools for cutting, drilling, and shaping. Be sure to use the right tools for the specific type of plastic you are working with to avoid damaging the material.

-

Follow safety guidelines: When working with plastics, it is important to follow safety guidelines to avoid injury. Wear gloves, safety glasses, and a respirator when cutting or shaping plastics, and work in a well-ventilated area to avoid inhaling fumes.

-

Consider sustainability: While plastics offer many benefits, they also have a significant environmental impact. When selecting a plastic type for your application, consider the environmental impact of the material and look for options that are recyclable or made from renewable sources.

-

Choose the right supplier: Working with high-quality plastics requires a reliable supplier who can provide consistent quality and timely delivery. Look for a supplier with a good reputation for quality and customer service.

In conclusion, high-quality plastics offer a wide range of benefits and uses, from optical clarity to high strength and durability. By selecting the right plastic type for your specific application and following safety guidelines when working with plastics, you can achieve excellent results and create products that are both functional and aesthetically pleasing. Additionally, by considering sustainability and choosing the right supplier, you can help minimize the environmental impact of plastic use and ensure a reliable supply of high-quality materials for your projects.

Applications:

Acrylic is a popular choice for use in aquariums, due to its excellent optical clarity and resistance to shattering. It is also commonly used in the production of skylights and windows, as well as in the construction of greenhouses and outdoor signage. Additionally, acrylic is a popular material for use in the production of display cases and museum exhibits, due to its ability to transmit light and its resistance to discoloration over time.

Polycarbonate is an excellent choice for applications where impact resistance is critical, such as the production of safety glasses, goggles, and face shields. It is also used in the production of automotive parts and electronic components, due to its excellent strength and durability. Polycarbonate is also commonly used in the construction of greenhouses, as it provides excellent light transmission while also protecting plants from damage due to impacts of extreme weather conditions.

Polyethylene is a popular choice for use in the production of packaging materials, due to its low cost, excellent durability, and resistance to chemicals and moisture. Additionally, polyethylene is commonly used in the production of water tanks and other liquid storage containers, due to its ability to resist corrosion and other forms of degradation over time.

Polypropylene is an excellent choice for use in the production of laboratory equipment and other applications where chemical resistance is critical. It is also commonly used in the production of food packaging, due to its ability to resist grease and other substances. Additionally, polypropylene is a popular choice for use in the production of toys and other consumer products, as it is both durable and lightweight.

Nylon is a strong and durable plastic that is commonly used in the production of gears, bearings, and other mechanical components. It is also used in the production of fishing line, ropes, and other textiles. Additionally, nylon is sometimes used in the production of medical equipment, due to its ability to resist abrasion and other forms of wear.

PVC is a versatile plastic that is commonly used in the production of pipes, electrical cable insulation, and window frames. It is also used in the production of flooring, wallpaper, and inflatable products. Additionally, PVC is sometimes used in the production of clothing and other textiles, due to its durability and resistance to moisture.