There’s a difference from normal floorings commonly used in the house, outdoor plastic wooden deck tiles are mostly used for balconies, corridors, offices, bathrooms, spa rooms. This type of DIY wooden deck tiles is increasingly interested in by people who love wood products. Therefore, today we will learn more about this product, let's see how outdoor natural Acacia interlocking tiles are manufactured.

Introduction of outdoor wooden deck tiles

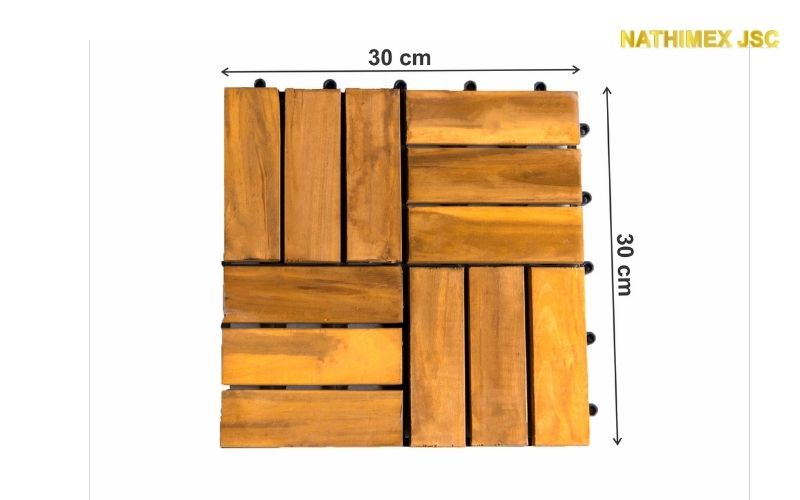

Our export standard wooden deck tiles specification is 30cm x 30cm x 2.4cm. Particularly, the thickness of wood slats has its minimum of 12mm.

The 12 wood slats tiles are arranged into the mold, also having plastic connectors system at the bottom.

Outdoor wooden deck tiles structure

Plastic base Bottom:

The base is made from PP plastic, so the base is always strong and tough.

When it comes to quality outdoor Acacia deck tile, the plastic base must be pressed into the wood slats to make the wooden deck tile sturdy and aesthetic.

Wood part on the top

Because the tiles are mainly used outdoors, the product must be able to withstand the rain and weather. In the light of this reason, Acacia wood becomes the most suitable wood for making plastic wood blisters outdoors.

Coating

Each company has their own unique color scheme formula. This makes a difference between companies. The color scheme not only needs to focus on helping the wood fight warping, moth,damages but also create an aesthetic, preserving the natural beauty of the wood.

How wooden deck tiles are manufactured?

Preparing Raw materials:

Acacia wood is cut into small slats, proceeding to polish the edges for beauty. Then cut the wood into the correct size to use.

Joining the raw wood billet into mold:

After the wood billet has been cut, depending on the type of slats on the design, we divide the different wood. Currently, NATHIMEX massively manufactures many types of Acacia wooden deck tiles such as 12 slats, 6 slats, diagonal 8 slats, 4 slats and so on.

Dipping into oil for wooden deck tile:

In the finished deck tile stage, the next step is to dip, wipe the oil and dry them on the drying rack. At this stage, it is common for factories to mix different colors to form a typical wooden deck tile representing the factory's own signatures. NATHIMEX humbly takes pride in being one of the enterprises with a pretty good sense of color scheme formula that meets the taste of global customers.

This process protects the wood from moisture and other environmental factors. The tiles are stacked in a pile, then dip them into the oil bath. They are left to soak for a few minutes, then they are removed and placed on the drying rack.

Drying wooden deck tiles on the rack:

Once the wood deck tiles have been dipped into oil, they need to be dried. The tiles are placed on the drying rack and left to dry out for several hours. The drying time can vary depending on the weather conditions and the humidity of the air. It is important to ensure that the tiles are completely dry before they are packaged.

Packaging:

Once the tiles have been dried, they are ready to be packaged. The tiles are stacked in a neat pile and wrapped with a strap to protect them during transportation. They are arranged to be put inside the carton box, ensuring the tiles also will not move or scratch the wood surfaces. All follow the customer's design.

This step guarantees that the tiles are not damaged during shipping and arrive in good condition to the end-users.

Loading cargoes:

Over the packaging done, carton boxes are stacked in a specific way to maximize the space inside the container.

By loading loose, carton boxes/ sets are arranged to match the container size. For the last layer of the carton boxes loaded, workers will reinforce it with straps.

By loading with a pallet, carton boxes/ sets are arranged to place permanently on the pallet. The pallets prevent them from shifting during transportation.

Finally, the container is then sealed and shipped to its final port. By following these steps, wood deck tiles can be transported safely and securely, and they will be ready to use when they arrive at their final destination.

Those are all parts of our manufacturing process days. Hope it better informs you about our products in detail.